How Important Are Garment Labels Wash Labels & Size Labels for Export Apparel Production?

- Pitsinee Pannasuriyaporn

- Jan 10

- 2 min read

In apparel production for international markets, garment labels are not just small details—they are a critical component related to import regulations, consumer trust, and overall brand professionalism.

1. What Are Garment Labels?

Garment labels are information tags attached to apparel products to communicate essential details to consumers and import authorities, such as:

Fabric content

Care instructions

Garment size

Country of origin

Manufacturer or distributor information (in some markets)

For export orders, labels are not optional extras.They are often a basic compliance requirement, and missing or incorrect labels may result in goods being delayed, rejected, or held at customs.

2. What Is a Wash Label and Why Is It Important?

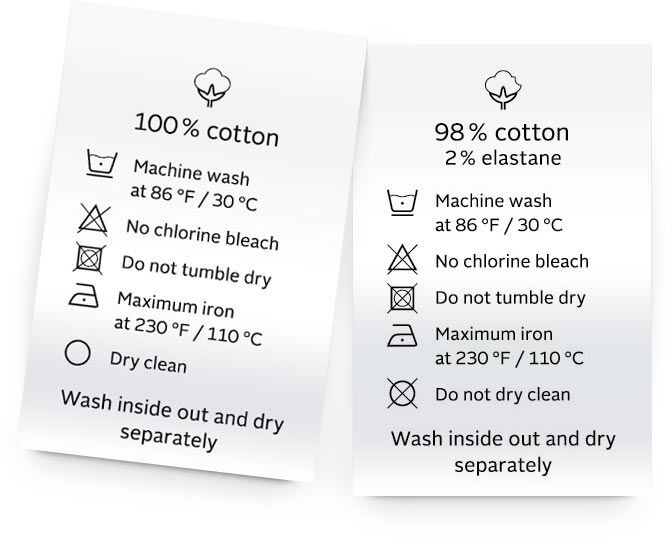

A Wash Label (also known as a Care Label) provides instructions on how to properly care for the garment.

Common Information on a Wash Label

Fabric content e.g. 100% Cotton / Cotton 60% Polyester 40%

Care instructions e.g. Machine wash cold, Do not bleach

Country of origin e.g. Made in Thailand

Why Wash Labels Are Essential for Export

Legally required in many markets, including:

United States (FTC regulations)

European Union

Australia

Helps prevent customs clearance issues

Reduces customer complaints and returns

Builds credibility and trust for the brand

3. What Is a Size Label and Is It Mandatory?

A Size Label indicates the garment size, such as S / M / L / XL, or EU and US sizing systems.

Common Size Label Formats

Sewn size label

Printed inner neck label

Size sticker on individual poly bags (in certain cases)

For Export Orders

Size labels are not legally mandatory in all countries

However, they are considered a global industry standard

Proper size labeling helps reduce confusion, returns, and customer dissatisfaction

5. Garment Labels in OEM & Export Production

For OEM apparel production intended for export, an experienced factory can assist in ensuring that:

Label content complies with destination market regulations

Language order and terminology are appropriate

Label format suits the fabric and garment construction

Planning garment labels from the sample development stage helps avoid production delays and simplifies the shipping process.

6. Conclusion: Small Details That Matter

In export apparel production,wash labels and size labels are essential components—not minor details. They reflect product quality, regulatory compliance, and the professionalism of the brand.Addressing labeling requirements early in the development stage helps ensure a smooth production and export process.

If you are looking for an OEM garment manufacturer in Thailand that can advise on garment labeling and export requirements, our team is happy to support you throughout every stage of production.

Comments